Backflow preventers are essential for protecting water supplies by stopping contaminated water from flowing backward into clean systems. Despite their importance, these devices can experience issues that compromise their effectiveness and lead to health and safety risks. Understanding the common problems backflow preventers face, their causes, and solutions is key to maintaining a safe and reliable plumbing system.

- What Are the Types of Backflow Preventers?

Backflow preventers are designed to protect water systems, but each type serves different needs and situations:

- Double Check Valve Assemblies (DCVA): Best for low-hazard situations, these use two check valves to block backflow.

- Reduced Pressure Zone Devices (RPZD): Designed for high-hazard conditions, these include a relief valve for added safety.

- Pressure Vacuum Breakers (PVB): Common in irrigation systems, these prevent back-siphoning during pressure drops.

- Atmospheric Vacuum Breakers (AVB): Simplistic and cost-effective, these work well for single-zone protection but lack versatility.

Each type has specific applications and limitations, making proper selection and installation crucial for effectiveness.

-

What Are the Common Issues with Each Type of Backflow Preventer?

What Are the Common Issues with Each Type of Backflow Preventer?

Backflow preventers are critical for ensuring water safety, but they are not immune to problems. Each type of backflow preventer has unique vulnerabilities due to its design and function. Here’s an expanded breakdown of common issues and how they can be addressed.

Double Check Valve Assemblies (DCVA)

- Problem: Internal seals and valves are prone to wear and tear over time, leading to leaks. When these components degrade, they compromise the preventer’s ability to stop backflow effectively.

- Solution: Routine inspections and timely replacement of worn-out seals or valves can prevent leakage and maintain optimal performance.

- Common Cause: Mineral buildup from hard water accelerates component degradation. This is particularly common in areas with high mineral content in the water supply.

Reduced Pressure Zone Devices (RPZD)

- Problem: Relief valves in RPZDs can become clogged with debris, rendering the device ineffective. This not only risks backflow but can also cause water pressure issues in the system.

- Solution: Periodic flushing and cleaning of the system are essential to remove debris and ensure smooth operation. Regular maintenance can also identify early signs of clogging before they become severe.

- Common Cause: Poor water quality, especially in areas with significant sediment or contaminants, often leads to clogging. Infrequent maintenance exacerbates the issue.

Pressure Vacuum Breakers (PVB)

- Problem: PVBs are particularly vulnerable to freezing temperatures, as the plastic components can crack when water inside them expands. This results in leaks and a loss of functionality.

- Solution: Winterization procedures, including draining the device and insulating it during colder months, can protect it from freezing damage.

- Common Cause: Outdoor installations in climates with freezing temperatures, especially when proper precautions are not taken, lead to frequent failures.

Atmospheric Vacuum Breakers (AVB)

- Problem: AVBs often fail due to improper installation or positioning, which can allow back-siphoning to occur. Since they rely on gravity and proper orientation, any deviation from manufacturer guidelines can render them ineffective.

- Solution: Ensuring professional installation and adherence to installation guidelines is crucial. Even minor deviations in positioning can lead to significant performance issues.

- Common Cause: DIY installations or lack of professional oversight are common culprits for improperly installed AVBs. These mistakes often go unnoticed until the device fails.

Understanding the common issues associated with each type of backflow preventer helps homeowners and businesses take proactive steps to ensure their systems function correctly. Proper maintenance, professional installation, and routine inspections are key to avoiding these problems and safeguarding water quality.

- Common Problems with Backflow Preventers Overall

While each type has specific issues, some problems affect all backflow preventers:

- Leaks and Drips: Caused by aging seals or cracks, leading to water loss.

- Reduced Water Pressure: Often due to blockages or misaligned parts.

- Corrosion: Found in older devices exposed to harsh conditions.

- Freezing Damage: Water left in the system freezes and expands, causing cracks.

Routine inspections and maintenance can catch these problems early and prevent expensive repairs.

- Signs Your Backflow Preventer Needs Repair

Spotting issues early can prevent costly damage. Look out for these warning signs:

- Unusual noises like clicking, banging, or hissing from the device

- Visible water leaks or pooling around the preventer

- Discolored or foul-smelling water indicating contamination

- Sudden drops in water pressure that disrupt daily activities

Addressing these signs quickly can prevent more severe failures and maintain water safety.

Also Read: 4 Signs Your Backflow Preventer Is Leaking And How To Fix It

- Why Regular Maintenance Is Critical

Backflow preventers are not a “set it and forget it” component. Regular maintenance ensures they remain effective and compliant with local regulations. Annual testing is often required, particularly for commercial systems. Maintenance typically involves clearing debris, replacing worn parts, and verifying functionality. Working with certified professionals ensures these tasks are done correctly and thoroughly.

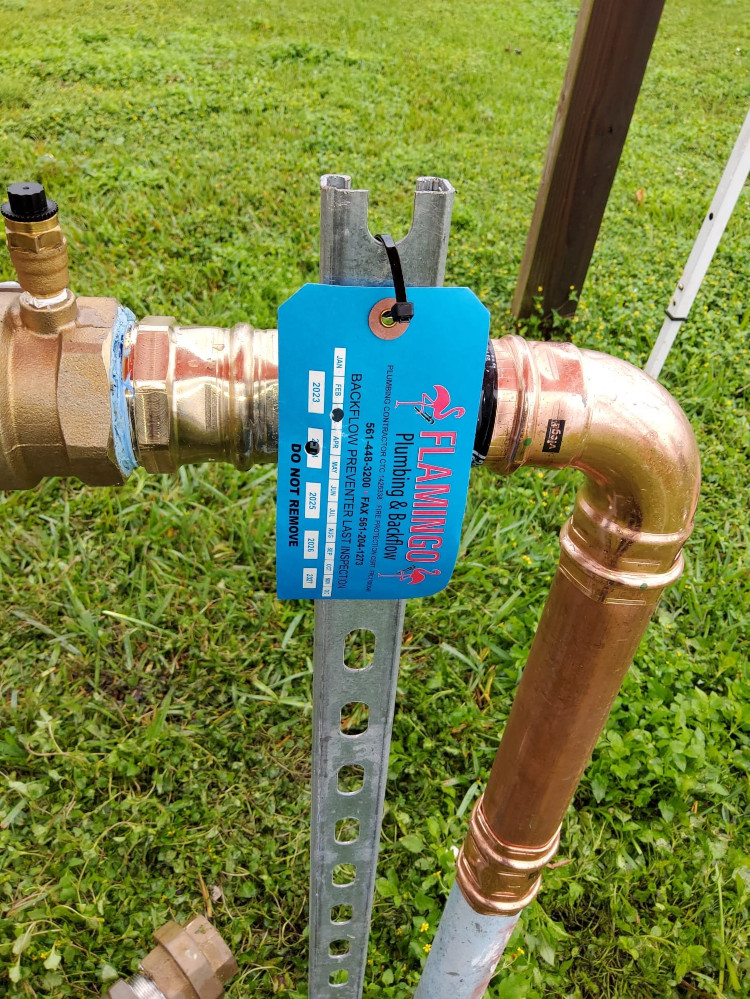

Expert Solutions for Backflow Preventer Problems in South Florida

Flamingo Plumbing & Backflow Services specializes in diagnosing and resolving all types of backflow preventer issues. Whether it’s installation, repair, or maintenance, our certified technicians ensure your system remains reliable and compliant with local regulations. Don’t let preventable problems jeopardize your water safety—trust us to provide the expertise and service you need to keep your system running flawlessly.